Habitat Door Handle Repair

A Simple Fix Done The Hard Way

On a recent trip to British Columbia’s north coast our habitat entry door exterior handle started having issues. I say started, but really it was a continuation of an earlier problem that I fixed back in 2022 when the plastic facia panel cracked across its width. Back then we repaired it by making an aluminum panel which was glued and screwed over top of the factory facia panel. It worked great until this more serious failure took place.

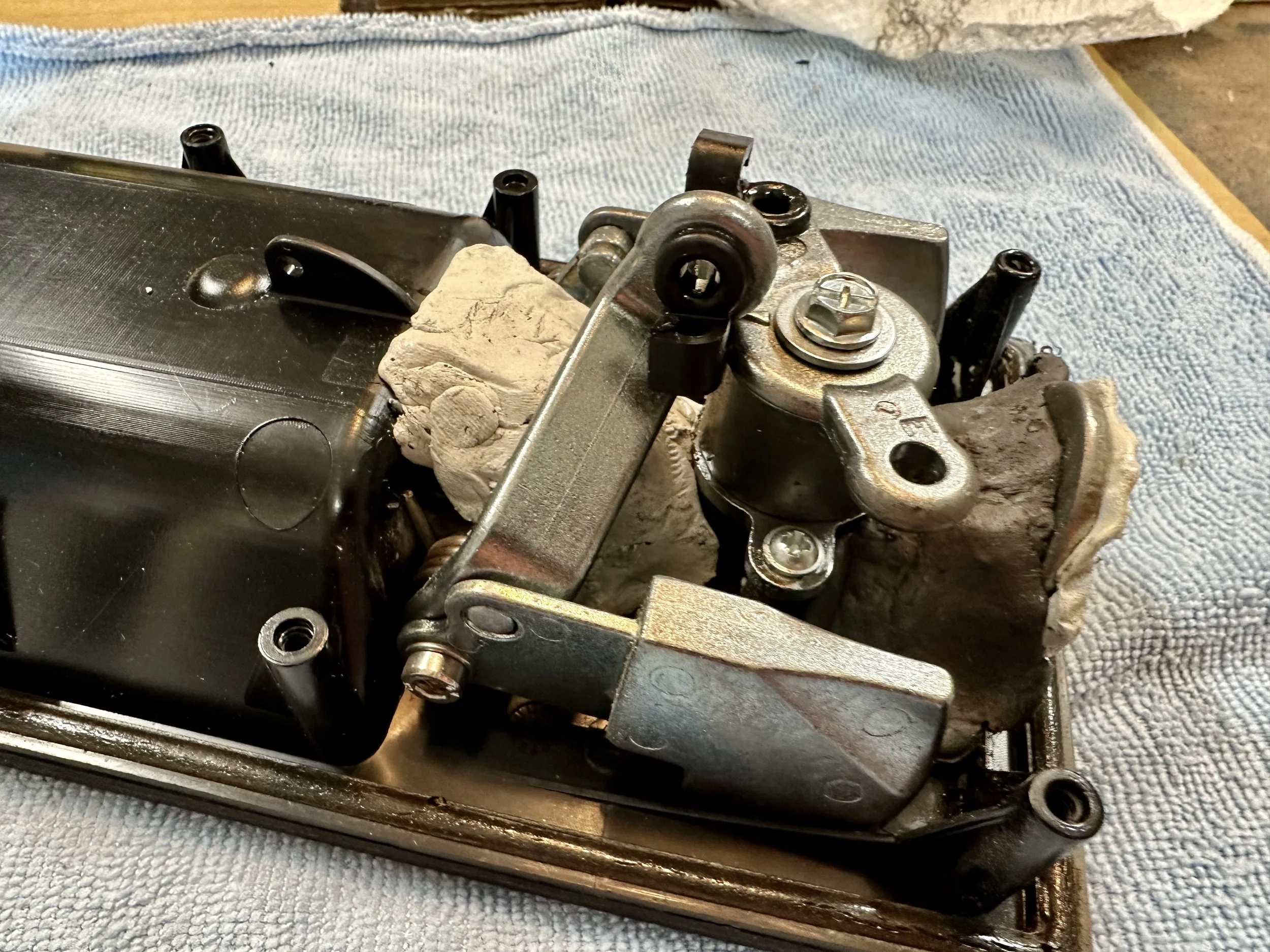

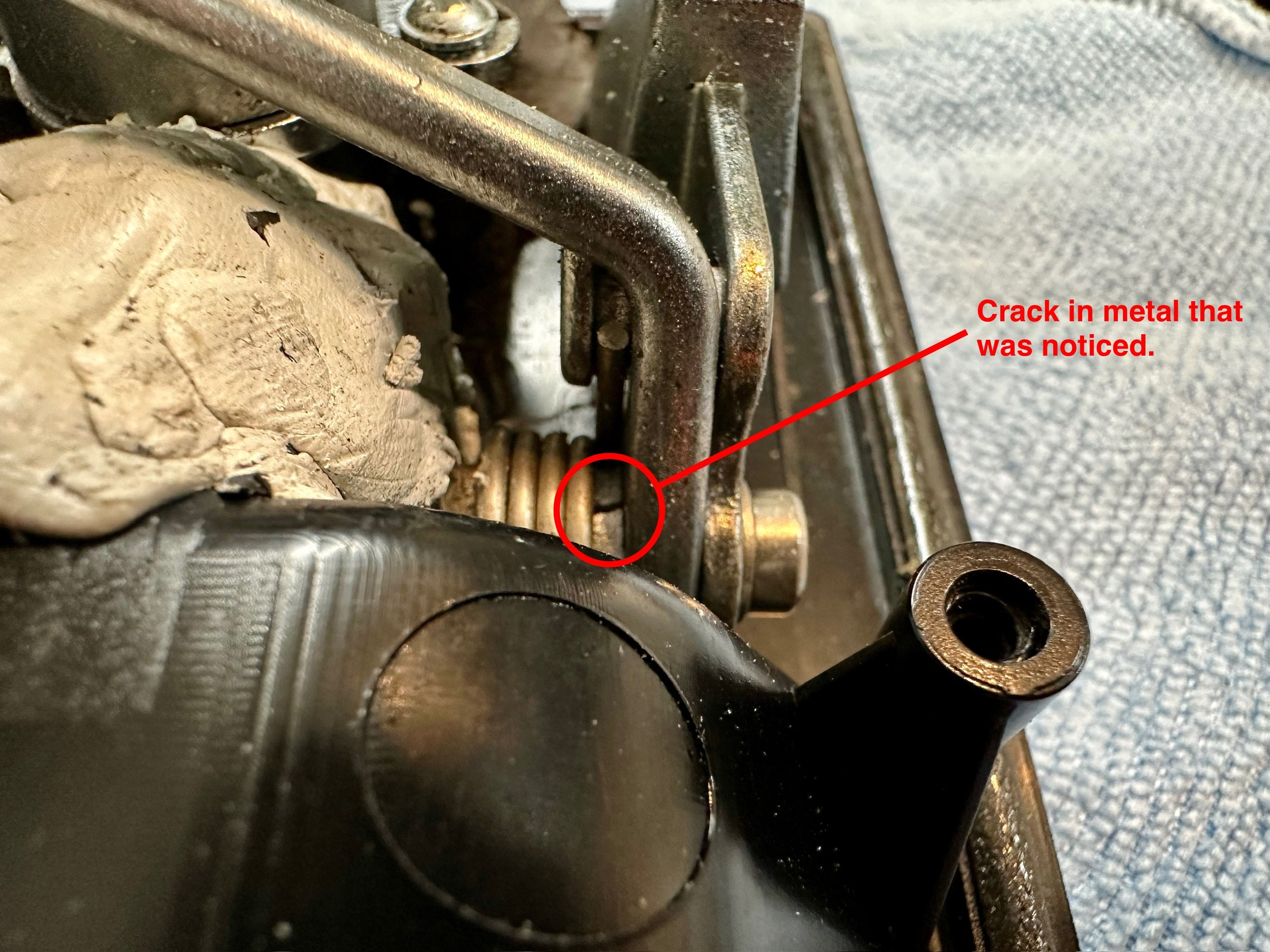

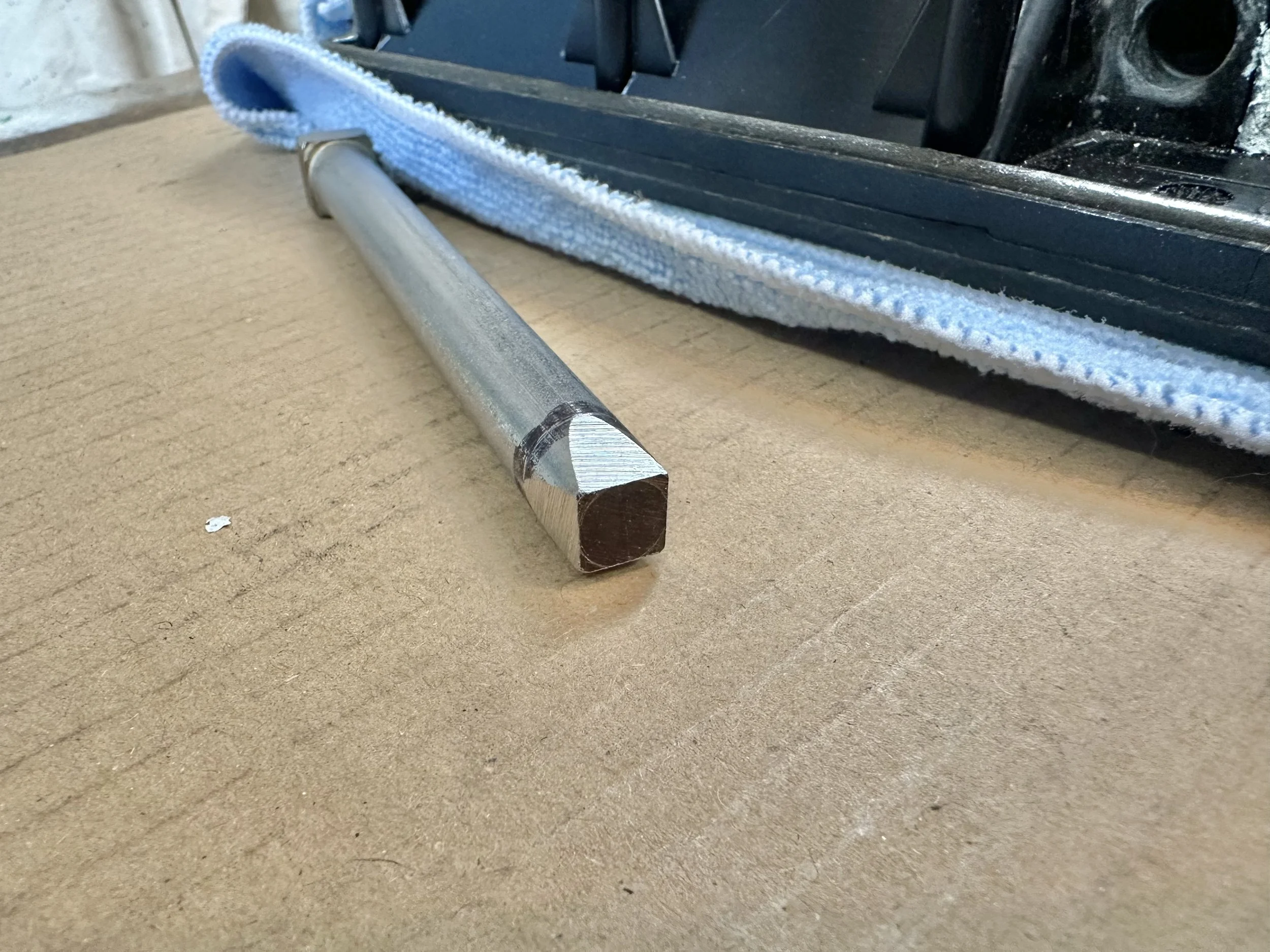

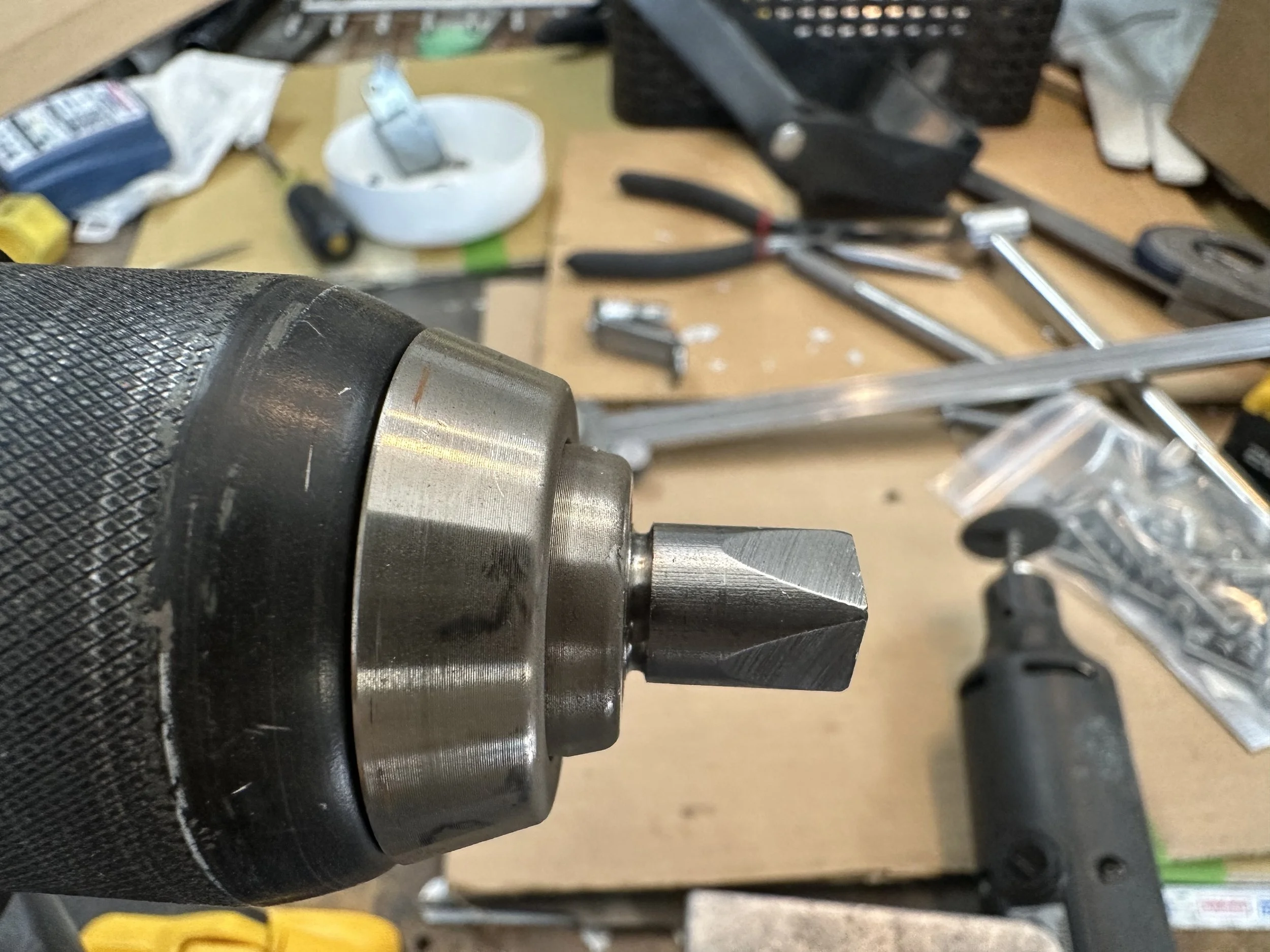

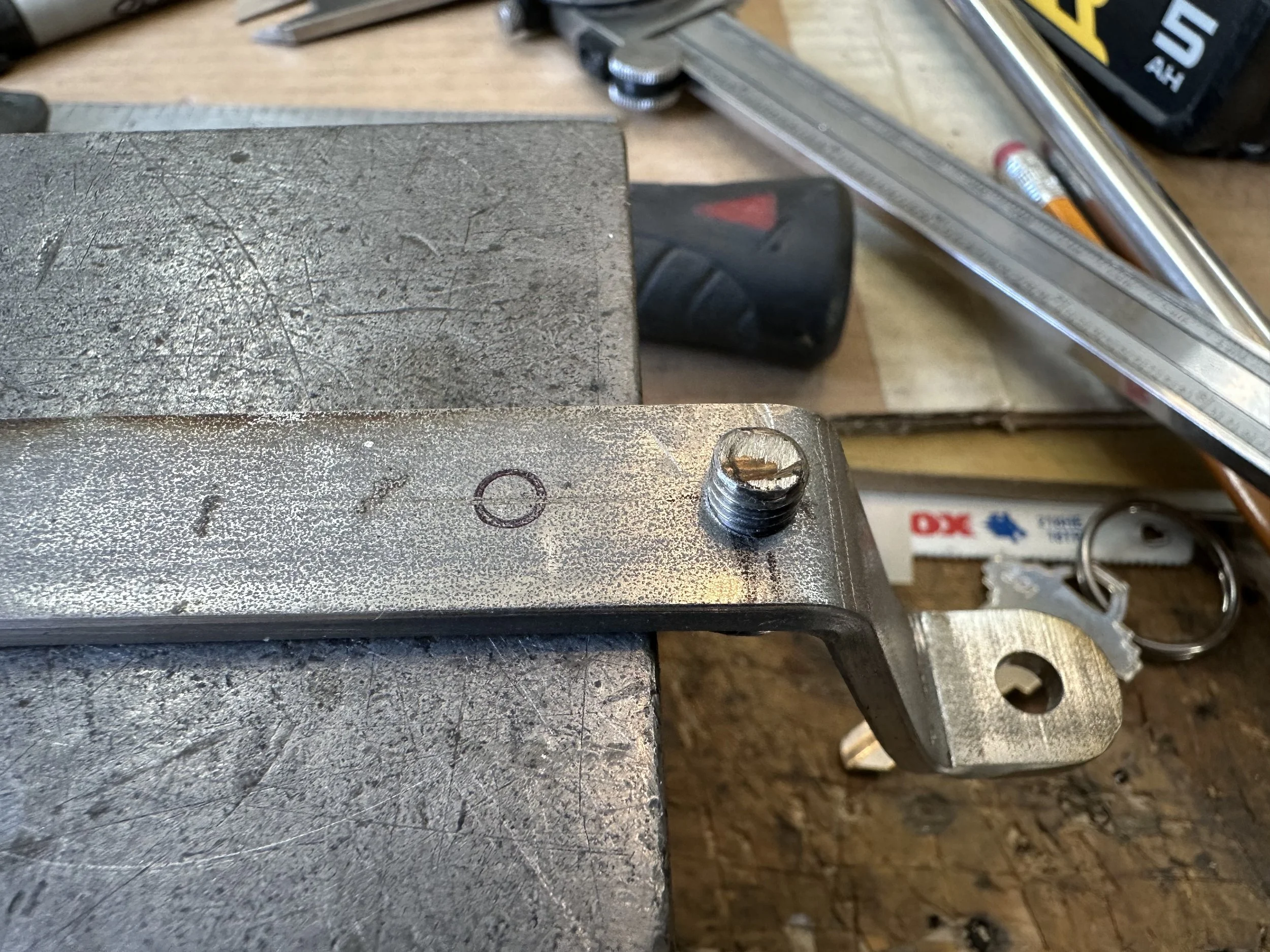

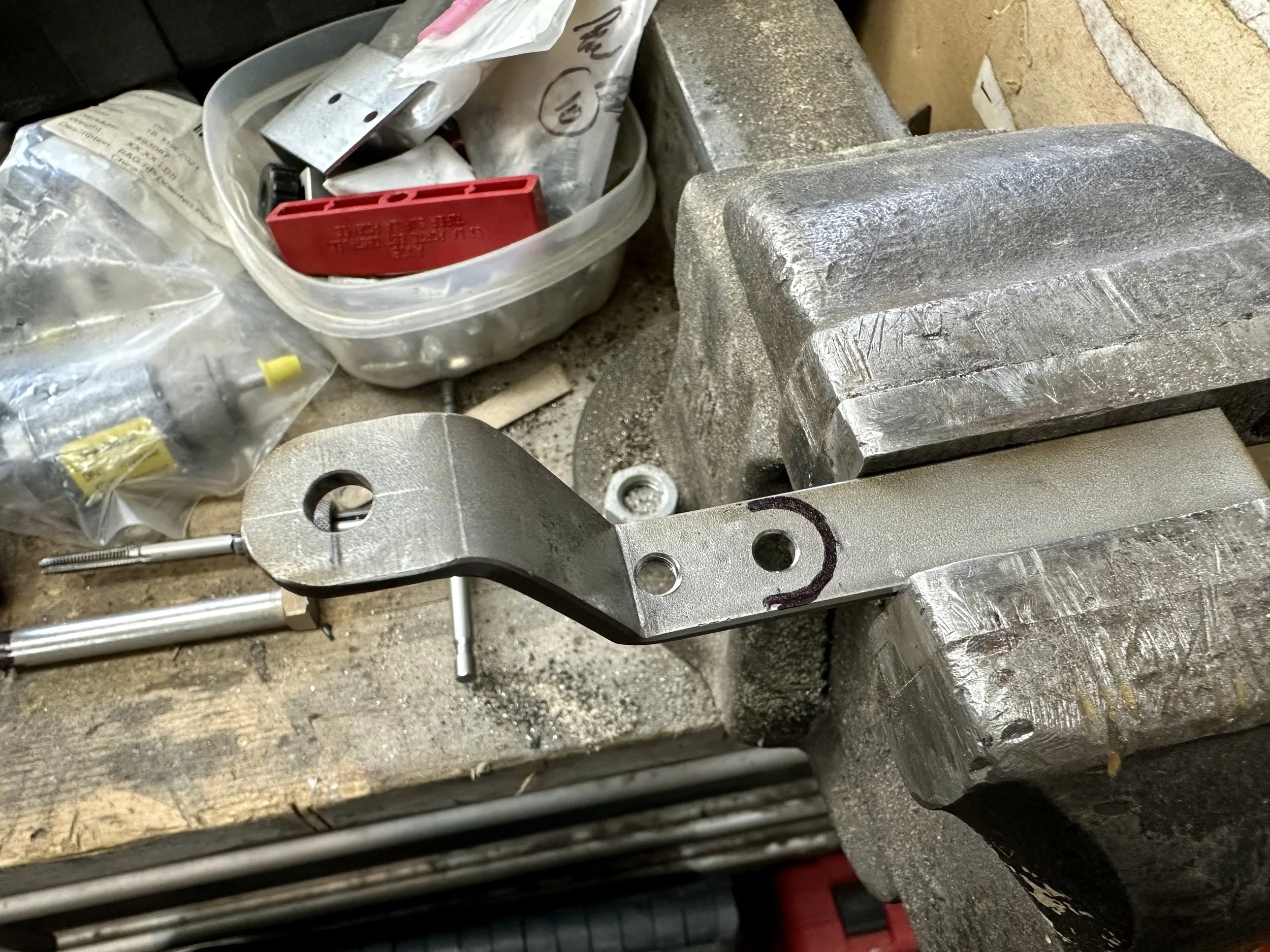

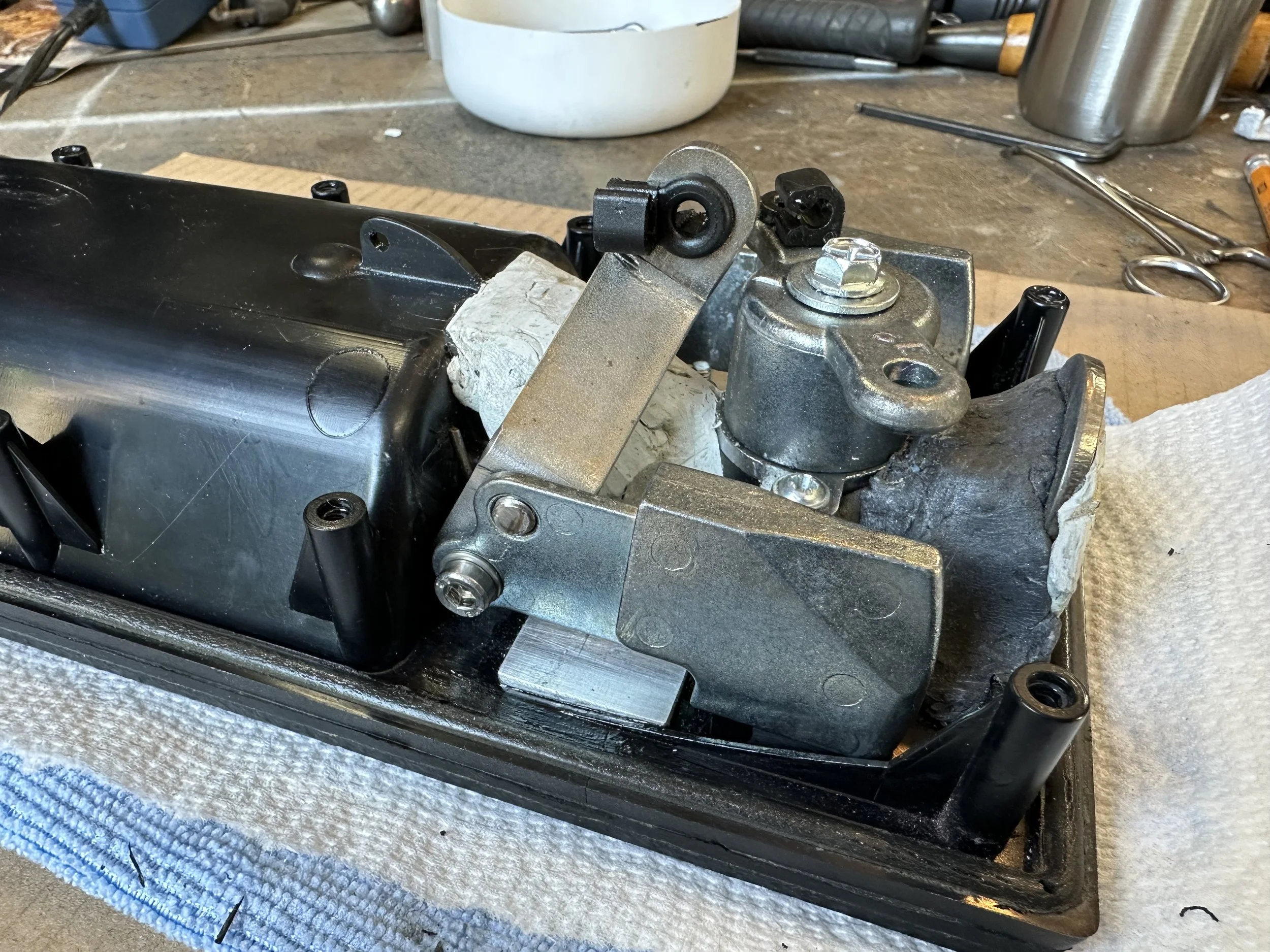

The crack migrated inside to the pivot housing where the mechanism that unlatches the door is located. The housing fractured in numerous places, the cause of which we would soon find out was a broken metal pivot axle. Made of some sort of cast metal, it broke completely in half and made it impossible to open the door from the outside. We were able to push the broken plastic housing back together with some CA glue, and then layer on some JB Weld epoxy putty to reinforce the break. Despite this field repair, the handle still wouldn’t open the door from the outside. Thank the heavens we have a pass through tunnel connecting to the truck cab. We were able to enter the habitat via this route to open the door from the inside. Fortunately the failure happened towards the end of the trip, so the inconvenience was reduced.

When we got back home we contacted the builder wanting to order a new outer door handle assembly. Something that should be easy since the door is made by a big German maker of RV door and accessories. We had to go through the builder as the German company, Hartal, would not deal with us directly. Unfortunarely, once again the builder let us down. They didn’t have any record of the door model from when they made the habitat, and for some bizarre reason, weren’t able to determine the door model from the photos we sent. Nor could Hartel in Germany, according to the builder. We had hoped for a better outcome since GXV had been purchased by Storyteller Overland. But alas, the saga of failure persists even now.

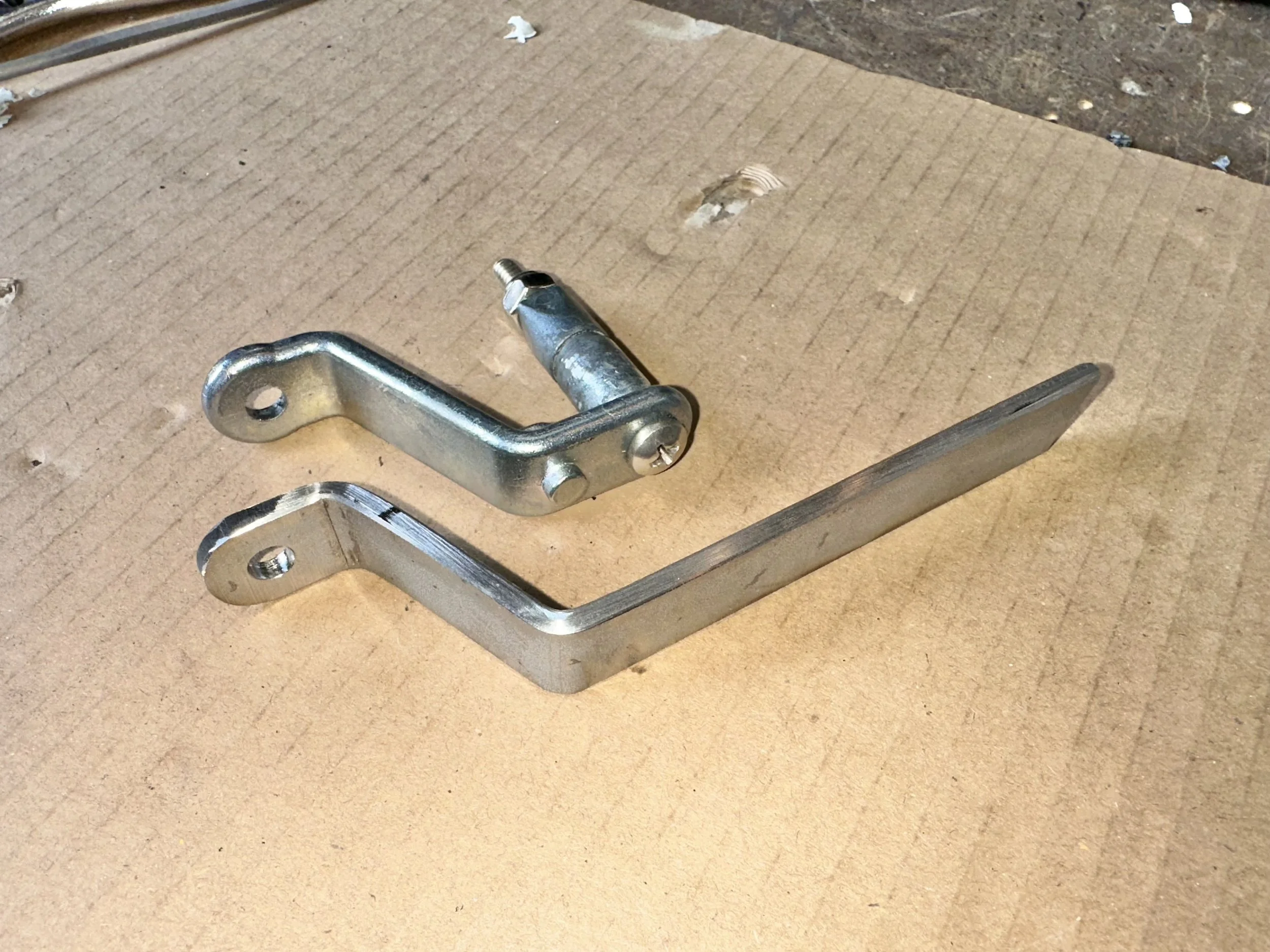

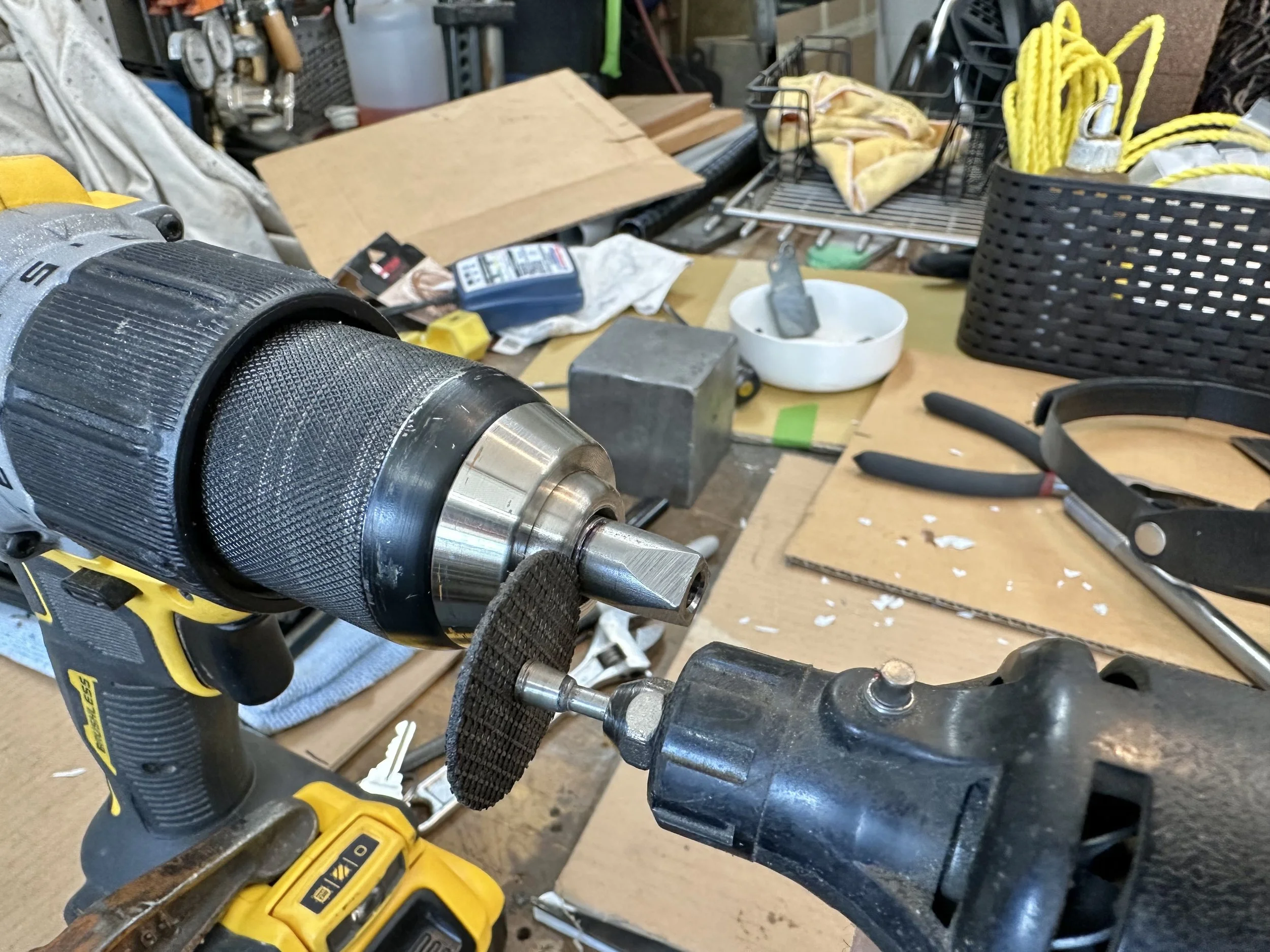

The only option was to see if we could repair the broken part ourselves. So off came the assembly, and the start of a two day reconstruction of the broken part.